A belt of knights

Aurora Simmons

June 23rd update: the belt is now finished and you can view lots of pictures of it here.

And here's a teaser. Scroll for the rest of the original blog.

Today I am honored to be featured in the blog of Christian Cameron, a fantastic historical fiction and fantasy author who happens to be a good friend.

He talks about craftsmanship through history and the complexities of accurate reproduction. The blog talks a lot about a new medieval knights belt I am working on, which has been both incredibly time consuming and also very rewarding. I hope you will read Christian's blog, but in addition I am including a small photo essay of the belt manufacture process.

If you would like to order a custom knights belt, they range in price from $550 to $800, please email me at info@handmaderevolution.org. We also have pre-made fittings which you can have assembled into a belt for around $350 to $400. You can view some of my other medieval belt work in our Historical section.

I can make custom modern belt buckles and belts as well, if such a thing strikes your fancy.

This is the heraldry I am working from. I will take elements of this flag an incorporate them into the belt.

This silk banner was made by my friend Bernard, you can view some of his other work here.

Next I create some waxes ( these I carve by hand) they look pretty unexciting until they are cast. Inspiration for the belt bar, belt end and buckle came from originals found in the Thames.

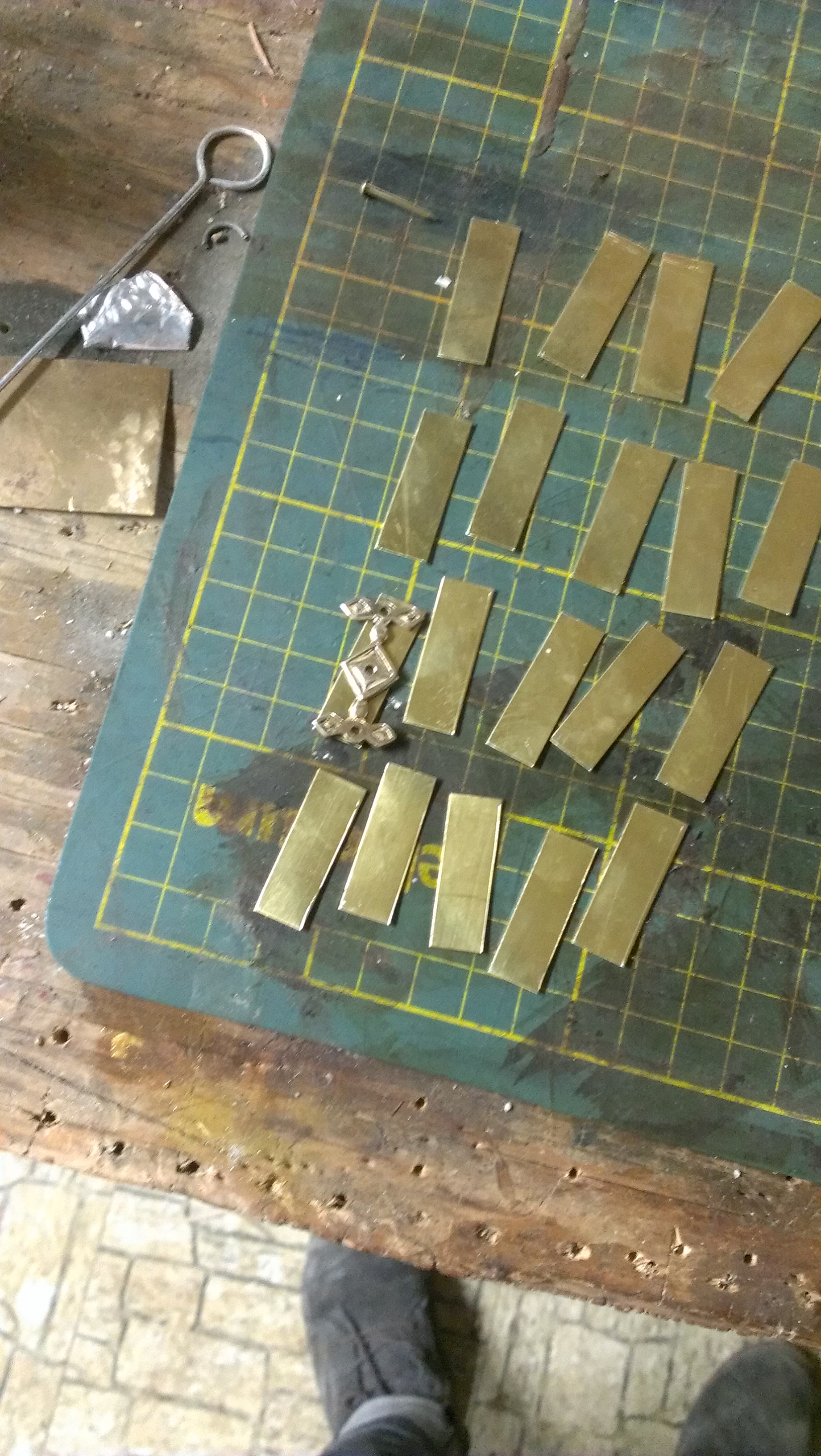

Once they are cast ( we cast 8 swans, 22 bars and 16 suns also one buckle and belt end) the entire weight of all the brass combined was almost 200 grams. I polish them up, a dirty and time consuming process, then the fun part starts.

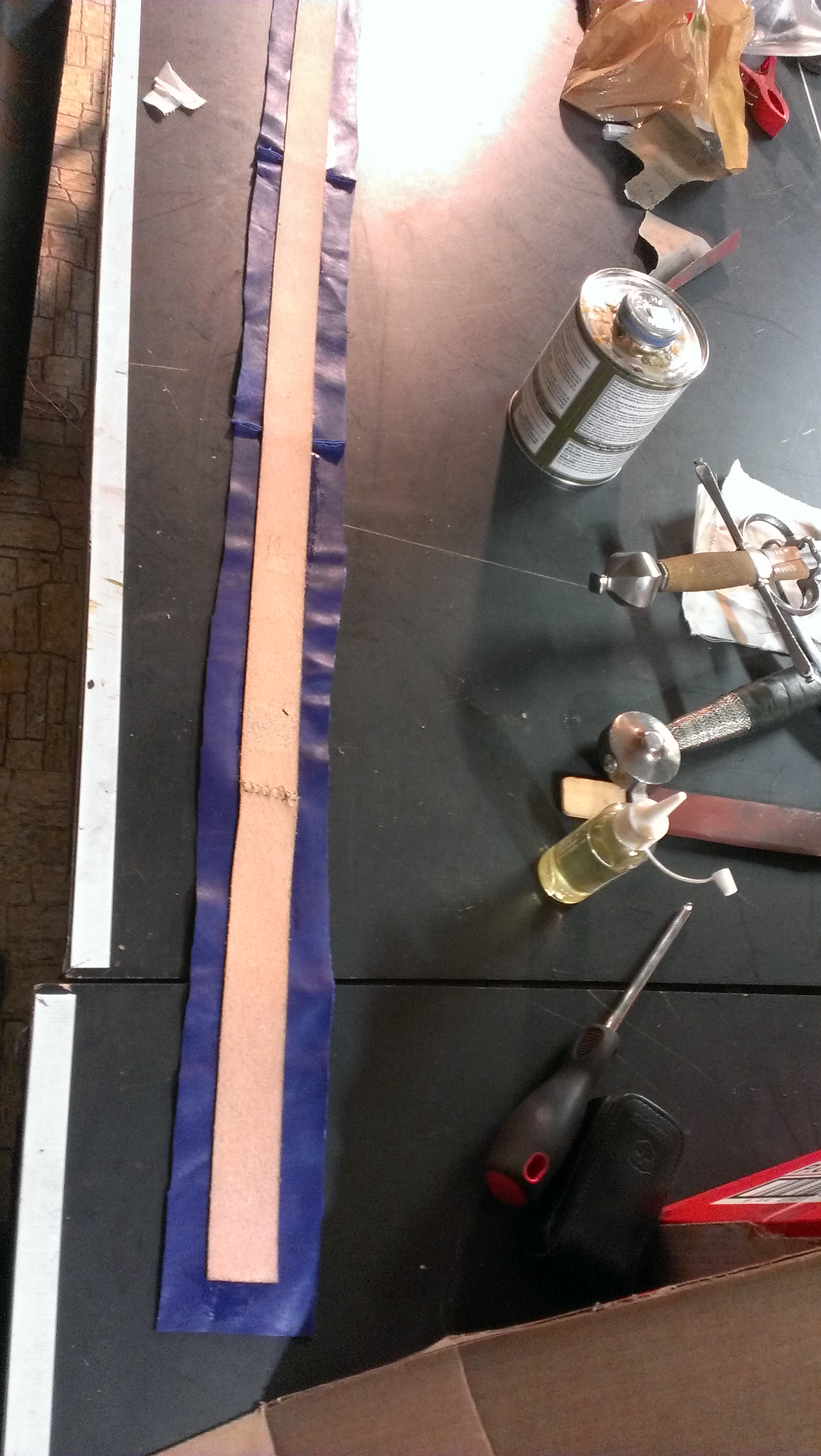

We decided to cover the belt in blue deerskin. The deerskin is very soft and supple so I can just wrap it around the heavier leather of the belt itself and then rivet through the whole thing.

This was actually a bad patch I took a picture of for reasons, but you get the idea.

Here are the fittings laid out with the belt. The length is 60 inches.

Each fitting needs a piece of brass to go on the back to be used as a washer so the rivets have something to catch in.

These fittings get three rivets each. The suns get one each and the swan plates have integral rivet pins.

Next, I use a hammer and soft wood to punch the brass pins through the fittings (which are pre-drilled) and washers, so the fit is really good.

I use some glue to attach the deerskin to the belt so I can accurately rivet through it. It will be sewn later.

Note the sword hilts. Because that's the sort of thing we have lying around in the workshop.

I use an awl and leather punch to punch holes through the leather and inset the fittings with the brass rivet pins.

Now I turn it over and use a riveting hammer to carefully smash the ends of the pins down until they are secure. This is where our shop anvil really comes in handy. That and a lot of swearing.

Now you can really see it coming together.

After all the rivets are done, I turn the belt over and sew up the back. The belt and and buckle get riveted on last. The belt end is waiting for some final touches so it doesn't show up super well here, but you should get the idea.

And there you have it. Soon I should have a picture of it complete and on the owner, but for now, here's one of me showing it off looking only slightly crazed (that was a lot of rivets).